Note: This product has been discontinued. View the latest product available here.

SIJ-320UV

High performance grand format LED UV inkjet printer

The all new Mimaki SIJ-320UV grand format LED UV inkjet printer delivers a unique combination of high quality super wide output for volume production of banners, retail and exhibition graphics and other similar applications up to 3.2m wide, with the added versatility of twin-roll simultaneous printing.

|

|

|

|

|

|

|

|

Create…

Indoor and Outdoor Signage, Exhibition and Display Graphics, Front and Backlit Signage, Retail PoS and much more…

Specifications, options and supplies of SIJ-320UV

Specifications

| Item | SIJ-320UV | |

| Head | On-demand piezo head (4 staggered printheads) | |

| Print resolution | 300dpi, 600dpi, 900dpi and 1200dpi | |

| Ink droplet size | Minimum: 7pl Maximum: 36pl | |

| Head gap (Manual adjustment) | 1.7mm / 1.9mm / 2.6mm / 3.3mm (Distance between the platen and the print head) | |

| Ink | Type | LED-UV ink LUS-120 |

| Colour | C, M, Y, K | |

| Packaging | 1 litre ink bottle, Ink can be filled up to 3 litres per ink colour. | |

| Maximum print width | 3,200mm | |

| Maximum media width | 3,250mm (Twin rolls printing with a small drive shaft: 1,524mm × 2) | |

| Minimum media width | 210mm | |

| Media thickness | 1.0mm or less | |

| Roll outer diameter | Large drive shafts: Φ250mm or less. Small drive shaft with roll holders: Φ180mm or less. | |

| Roll weight | Large drive shafts: 100kg or less. Small drive shaft with roll holders: 25kg or less | |

| Dimensions (W × D × H) | 5,410mm × 995mm × 1,440mm | |

| Shipping dimensions (W × D × H) | 5,750mm × 1,140mm × 1,210mm | |

| Weight | 850kg | |

| Power supply | AC 200 – 240V ± 10% 50/60 Hz ± 1 Hz, 15 A or less | |

| Power consumption | 3.6kW or less | |

| Operational environment | Temperature | 20 – 30 °C (68 – 86 °F) |

| Humidity | 35 – 65%Rh (No condensing) | |

| Temperature accuracy | 20 – 25 °C (68 – 77 °F) | |

| Temperature gradient | Less than ± 10 °C/h (± 18 °F/h) | |

| Dust | 0.15mg/m3 (Equivalent to normal office level) | |

Supplies

| Item | Colour | Item No. | Remarks |

| LED-UV Ink LUS-120

| Cyan | LU12-C-BA | 1L ink bottle |

| Magenta | LU12-M-BA | ||

| Yellow | LU12-Y-BA | ||

| Black | LU12-B-BA |

Features of SIJ-320UV

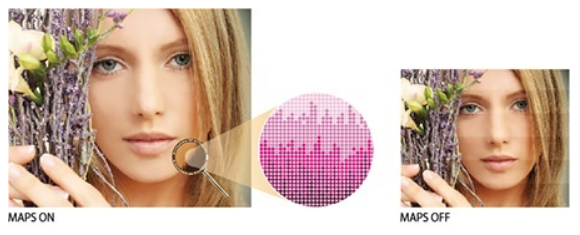

MAPS4 (Mimaki Advanced Pass System) anti-banding system

Mimaki’s unique MAPS3 anti-banding system has been improved to MAPS4. Unwanted visible banding on the swath boundaries is reduced by overprinting between swaths with a reduced number of ink droplets.

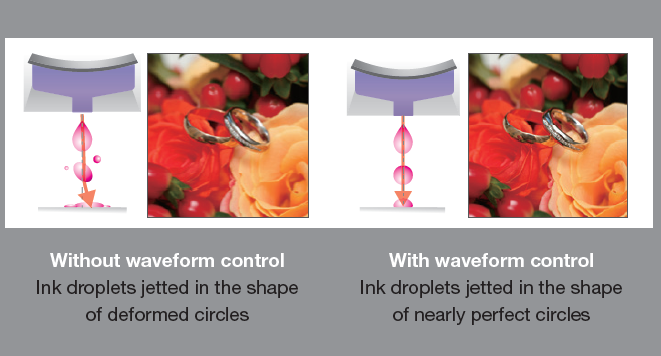

Waveform control technology

Ensures high quality print resolution, by jetting ink drops in straight lines with almost perfect round dots, delivering clear and sharp letters, lines and edges.

Superior inkjet technology

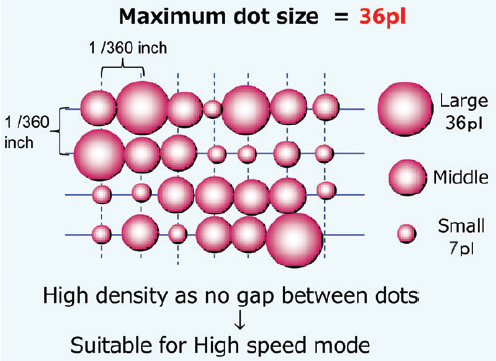

Mimaki’s superior inkjet technology accurately places the ink droplets without losing their perfect circularity, delivering high density print by removing the gap between dots. This ensures that texts, lines and edges are clearly and sharply printed.

New image-processing technique reduces tone jumps and uneven colour printing

Mimaki Fine Diffusion 1 (MFD1) has been recently added to the bundled RasterLink6 RIP software. MFD1 reduces the noise that is generated in image data during image processing and enables the production of better print results without tone jumps or uneven colours.

Smooth gradation printing

Various ink droplet sizes (large, medium, and small) are precisely placed and exhibit non-grainy, smooth, large-format printing. Dark and light colour differences are clearly presented, even in high-speed mode, by utilising the largest 36pl droplet size.

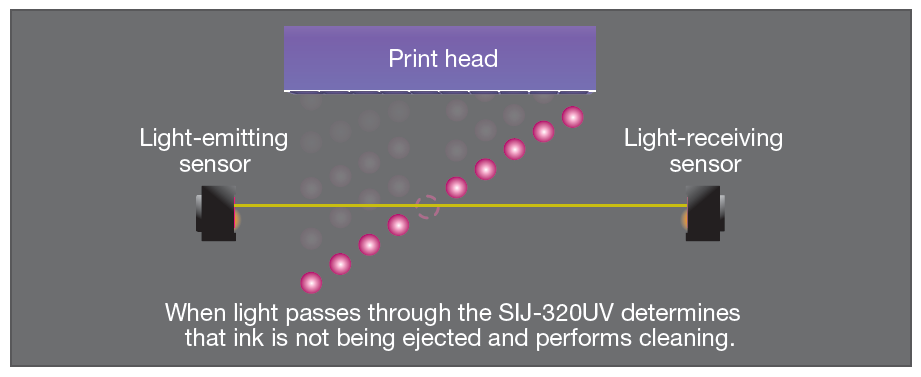

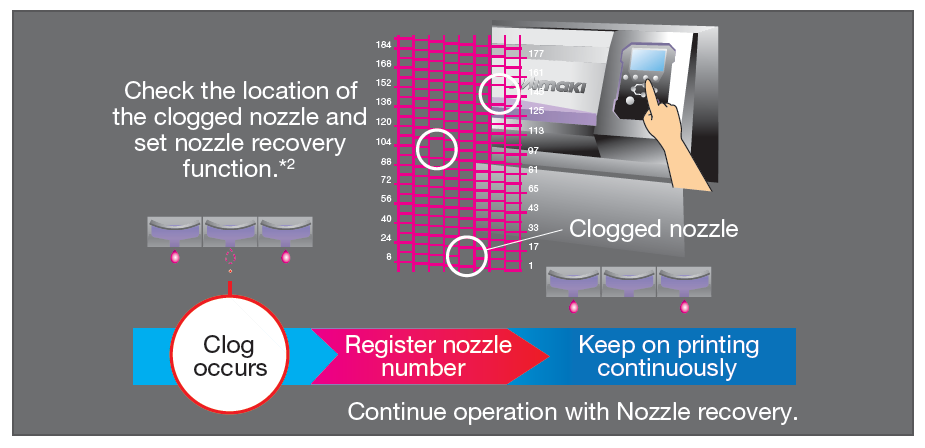

NCU (Nozzle Check Unit) prevents print quality problems

The SIJ-320UV is equipped with Mimaki’s original automatic NCU. Clogged nozzles are automatically detected and cleaned by the NCU. If the clogging is not resolved by cleaning, the SIJ-320UV automatically sets the nozzle recovery function NRS and resumes printing. These functions significantly reduce the waste printing caused by clogged nozzles during a continuous printing run.

NRS (Nozzle Recovery System) for productivity maintenance

The NRS substitutes defective nozzles with non-defective nozzles until the technician arrives. This feature enables uninterrupted print operations and continuous productivity.

*2. 10 nozzles per nozzle row can be registered

Efficient and versatile twin-roll simultaneous printing

Taking advantage of the 3,200mm printing width, two media rolls can be mounted for simultaneous printing. Different print jobs (or the same print job) can be printed on two separate rolls. The user can select the preferred width separately for each roll, within a specified range (210 to 1,524mm).

Simple media loading and advanced media feeding mechanism

With the improved safety design, rolled media can be easily loaded, reducing preparation time. While the newly designed print rollers provide more accurate media transportation, enabling high printing quality.

LUS-120: Newly developed, high-performance UV curing ink

The newly developed, high-performance LUS-120 UV curing ink possesses superior durability and flexibility. These two opposite properties provide beautiful and durable printing on flexible banner materials that cannot be laminated.

High speed (4-color: C M Y K)

Super-draft mode allows rapid printing at a maximum printing speed of 110 m2/h. High-density print mode is available for front/backlit signage applications.